In the process of using soybean oil manufacturing machines, many users often fall into some maintenance misunderstandings, which lead to unnecessary equipment wear and tear. For example, some users neglect daily cleaning, thinking that as long as the machine can operate, there is no need for frequent cleaning. However, over time, oil residue and impurities will accumulate inside the machine, affecting the normal operation of key components and reducing the service life of the equipment. According to industry statistics, improper maintenance can reduce the service life of a soybean oil manufacturing machine by about 30%.

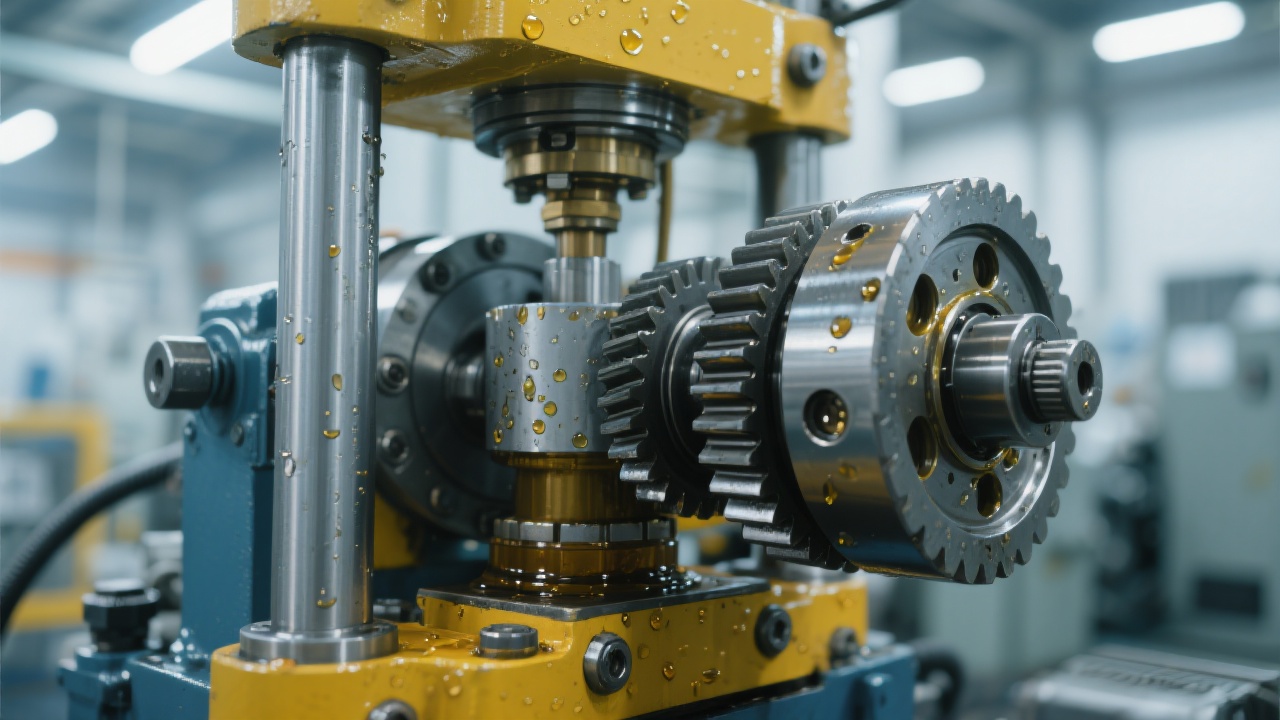

Soybean oil manufacturing machine in operation" style="width: 100%; margin: 20px 0;">

Soybean oil manufacturing machine in operation" style="width: 100%; margin: 20px 0;">

Different types of oil presses, such as screw, hydraulic, and integrated oil presses, have different structural characteristics, so their maintenance requirements also vary. For screw oil presses, the screw is the core component, and its wear directly affects the oil extraction rate. Regular inspection and replacement of the screw are necessary. In contrast, hydraulic oil presses require more attention to the hydraulic system, including the inspection of hydraulic oil quality, oil level, and the tightness of pipelines. Integrated oil presses, which combine multiple functions, need a more comprehensive maintenance plan.

| Oil Press Type | Key Maintenance Points |

|---|---|

| Screw Oil Press | Inspect and replace the screw regularly |

| Hydraulic Oil Press | Check hydraulic oil quality, oil level, and pipeline tightness |

| Integrated Oil Press | Comprehensive maintenance of all components |

The core components of soybean oil manufacturing machines, such as the screw, heating system, and filtration device, need regular inspection and replacement. For the screw, if the wear exceeds 2mm, it should be replaced in time to ensure the oil extraction rate. The heating system should be checked for proper temperature control and heating efficiency. If the temperature deviation exceeds ±5°C, maintenance or replacement is required. The filtration device should be cleaned or replaced monthly to ensure the quality of the oil.

A scientific maintenance cycle is crucial for the normal operation of soybean oil manufacturing machines. Here is a recommended maintenance cycle:

Scientific maintenance can significantly improve the oil extraction rate, reduce energy consumption, and extend the equipment life. According to industry data, regular maintenance can increase the oil extraction rate by about 5% - 10%, reduce energy consumption by about 15% - 20%, and extend the equipment life by about 50%. For example, a factory that implemented a scientific maintenance plan saw a significant increase in oil extraction rate and a decrease in energy consumption, which effectively reduced the operating cost and improved the competitiveness of the enterprise.

By mastering the correct maintenance and repair skills of soybean oil manufacturing machines, you can ensure the efficient operation of the equipment, reduce the risk of downtime, and improve the stability of oil extraction rate and quality. This will help your enterprise achieve sustainable production goals, enhance efficiency, reduce operating costs, and ensure continuous production. If you want to learn more about soybean oil manufacturing machine maintenance and repair, click here to get more professional guidance and solutions.