In recent years, the development trend of automation and intelligence in agricultural technology has become increasingly prominent. In modern farm management, these advanced technologies not only improve production efficiency but also reduce labor costs and resource waste. According to industry research, farms using automated and intelligent equipment can increase production efficiency by up to 30% compared to traditional farms.

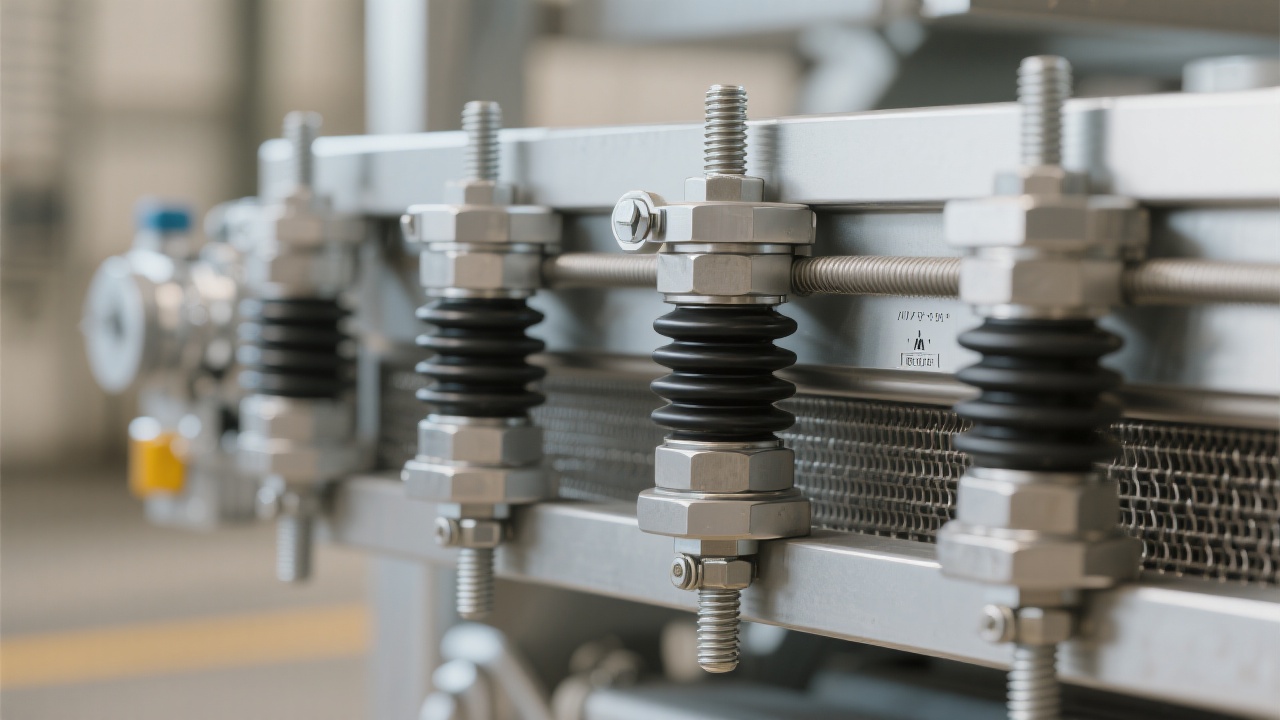

QI'E Group's 20tph palm kernel oil production line is a remarkable product in the field of palm oil processing. Its design concept is centered around high - efficiency, reliability, and intelligence. The production line is equipped with advanced PLC control systems, which can precisely control every production process. The technical specifications of the production line are also top - notch, with a high - quality oil extraction rate and stable production capacity.

The core competitiveness of this production line lies in its high degree of automation and intelligence. For example, the PLC control system can adjust production parameters in real - time according to different raw material qualities and production requirements, ensuring the stability and quality of the oil production. It also has multiple operation modes, such as manual, semi - automatic, and fully automatic, which can meet the needs of different users.

The automation and intelligence of the 20tph palm kernel oil production line are manifested in many aspects. The PLC control system is like the "brain" of the production line, which can monitor and control the entire production process. Through sensors and feedback mechanisms, it can detect the temperature, pressure, and flow rate of each process, and make timely adjustments. In addition, the production line also has a self - diagnostic function, which can quickly identify and solve problems when a fault occurs.

This production line is suitable for a variety of scenarios, including food and beverage factories and farms. In food and beverage factories, it can provide high - quality palm kernel oil as raw materials for product production. In farms, it can process palm kernels on - site, reducing transportation costs and improving economic benefits. Compared with traditional production lines, it can save up to 20% of energy consumption and reduce labor requirements by 30%.

"Since we installed QI'E Group's 20tph palm kernel oil production line, our production efficiency has increased by 40%. The quality of the palm kernel oil has also been significantly improved, which has helped us expand our market share." - A farm owner in AsiaIn Africa, a food and beverage factory introduced this production line and reduced its production cost by 15% within one year. In South America, a large - scale farm increased its annual output value by 25% after using the production line. These cases fully demonstrate the effectiveness of the production line in improving production efficiency and economic benefits.

QI'E Group provides comprehensive technical support and services, including design, installation, commissioning, training, and quality assurance. The professional technical team can ensure that the production line is installed and commissioned smoothly, and provide in - depth training for the operators. In the quality assurance period, QI'E Group provides free maintenance and repair services, ensuring the long - term stable operation of the production line.

In conclusion, QI'E Group's 20tph palm kernel oil production line has significant advantages in terms of automation, intelligence, production efficiency, and economic benefits. It is a reliable choice for farms and food and beverage factories. If you are interested in this product or want to learn more about its details, please click here to contact us. We believe that with the development of intelligent agriculture, this production line will play a more important role in the future.