In the world of edible oils, soybean oil stands out as a staple for millions of households and businesses globally. It's not just a cooking essential but also a product of a sophisticated and well - orchestrated production process. Today, we embark on a journey to uncover the intricate steps involved in soybean oil production, highlighting the professionalism and strict quality control of our company.

The process starts with the arrival of high - quality soybeans at our facilities. On average, we receive over 500 tons of soybeans per week from trusted suppliers. Once received, the soybeans are thoroughly cleaned to remove any impurities such as dirt, stones, and broken beans. This step is crucial as it ensures the purity of the final product. Specialized cleaning equipment, like vibrating screens and air aspirators, are used to achieve this. For instance, a vibrating screen can sift out particles as small as 2mm, guaranteeing a clean batch of soybeans for further processing.

After cleaning, the soybeans are broken into smaller pieces and dehulled. The hulls, which make up about 8% - 10% of the soybean's weight, are removed as they contain little oil and can affect the quality of the extraction process. This is done using cracking rolls and dehullers. The dehulled soybeans are then ready for the next stage, which is flaking.

The dehulled soybeans are rolled into thin flakes. This increases the surface area for oil extraction. The flakes are then cooked at a precise temperature, usually around 100 - 110°C, for a specific period. Cooking not only helps in breaking down the cell structure of the soybeans but also inactivates enzymes that could cause off - flavors in the oil. Our company uses advanced cooking technology to ensure uniform heating and optimal oil extraction.

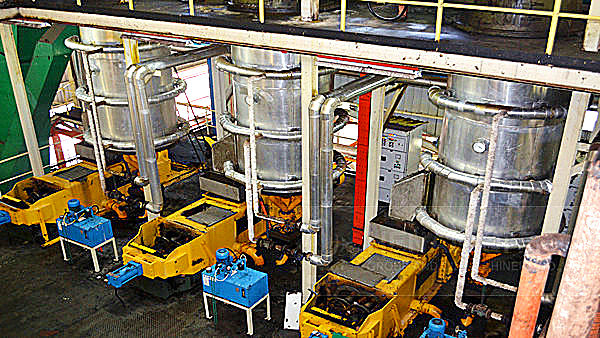

The cooked flakes are then subjected to oil extraction. We use a solvent extraction method, which is highly efficient, extracting up to 95% of the oil from the soybeans. Hexane is commonly used as the solvent. After extraction, the solvent is removed from the oil through evaporation and condensation, and the recovered solvent is reused, demonstrating our commitment to resource efficiency and environmental sustainability.

The crude soybean oil obtained from extraction is then refined to remove impurities, free fatty acids, and other unwanted substances. The refining process includes degumming, neutralization, bleaching, and deodorization. Through these steps, we ensure that our soybean oil meets the highest quality standards. For example, the deodorization process reduces the peroxide value to less than 1 meq/kg, which is well below the industry standard of 3 meq/kg, ensuring a longer shelf - life and better taste.

Soybean oil production doesn't just yield high - quality oil. It also generates valuable by - products. The soybean meal left after oil extraction is a rich source of protein and is widely used in animal feed. Annually, we produce over 200,000 tons of soybean meal, which is supplied to farms across the region. This showcases our company's commitment to resource utilization and environmental protection.

In conclusion, the production of soybean oil is a complex and highly professional process. Our company adheres to strict quality control measures at every step, from the selection of raw materials to the final packaging. We are also dedicated to environmental sustainability through efficient resource utilization. When you choose our soybean oil, you are choosing a product of excellence and reliability.

Partner with us and experience the difference in taste, quality, and sustainability. Contact us today to start your procurement journey!