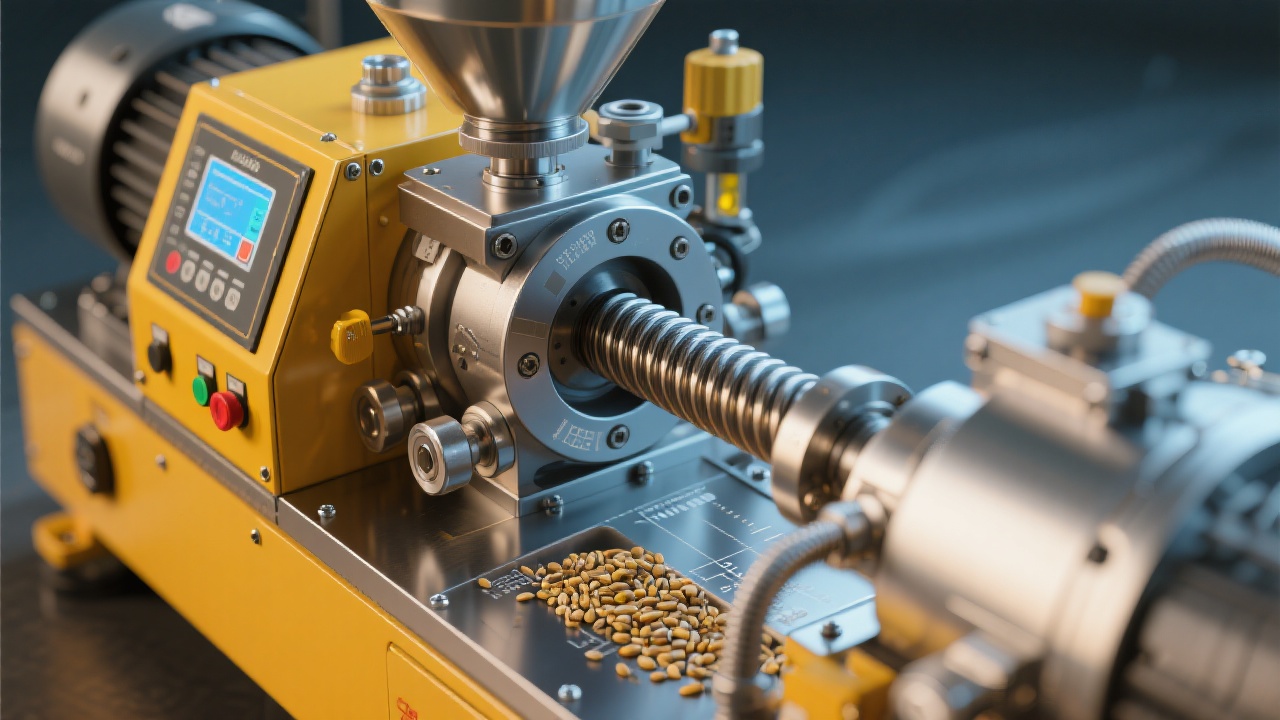

Understanding Key Equipment Types & Their Applications

Soybean oil refining equipment plays a crucial role in the vegetable oil industry, impacting production efficiency and product quality across international markets. Four dominant categories—batch (intermittent) refining machines, continuous refining machines, semi-automatic refining machines, and mini refining machines—each serve unique operational scopes and enterprise scales.

Batch refining machines appeal to small- and medium-sized enterprises seeking flexibility with moderate production volumes. Their intermittent operation allows precise control over each refining stage, which is vital when processing varying batch qualities.

Continuous refining machines

Semi-automatic refining machines bridge the gap for midsize players by combining automation with manual oversight to balance cost and operational control.

Lastly, mini refining machines serve niche markets and emerging economies, offering compact dimensions suitable for lower capital expenditure environments with production demand typically below 50 tons per day.

Analysis of leading international markets reveals differentiated equipment adoption patterns driven by production scale, capital availability, and local regulatory requirements. For instance, Latin American and Southeast Asian companies predominantly employ semi-automatic and batch refining machines due to balanced cost-efficiency and technological reliability, yielding annual output increases of 15%-20% with equipment investments amortized within 3-4 years.

In contrast, North American and European enterprises invest heavily in continuous refining systems to meet stringent food safety standards and large consumer base demands. These investments boost processing efficiency by up to 30%, reducing operational labor hours by 25% and increasing overall product consistency.

Furthermore, mini refining machines have gained traction in African and South Asian markets, offering affordable entry points that enable local SMEs to expand oil refining capabilities with minimal infrastructure. This sector reports an average annual growth rate exceeding 12% driven by rising domestic edible oil consumption.

| Equipment Type | Typical Production Capacity (tons/day) | Primary Markets | Key Advantages |

|---|---|---|---|

| Batch (Intermittent) Refining Machine | 50 - 300 | Southeast Asia, Latin America | Operational flexibility, lower upfront costs |

| Continuous Refining Machine | 300 - 1000+ | North America, Europe | High throughput, automation, food safety compliance |

| Semi-automatic Refining Machine | 100 - 500 | Emerging markets, mid-sized enterprises | Balanced cost and control |

| Mini Refining Machine | Below 50 | Africa, South Asia | Compact size, low investment, accessible |

The global soybean oil refining equipment market is influenced by key factors such as evolving food safety regulations, technological innovation, and growing consumer demand for refined edible oils. Over the past five years, international standards from agencies like WHO and FDA have elevated the requirements for oil purity and safety, pressuring manufacturers to upgrade their refining solutions to ensure compliance.

Concurrently, innovations integrating IoT automation and energy-efficient processes have increased equipment attractiveness by improving yield rates by 8%-12%, while reducing energy consumption. Market intelligence reports forecast a compound annual growth rate (CAGR) of approximately 7.4% globally in refining equipment demand through 2028.

Regionally, Asia Pacific is poised for the strongest expansion, driven by rising soybean cultivation, rapid industrialization, and increasing edible oil consumption, mirroring a 10% annual growth in machine adoption.

Success in exporting soybean oil refining equipment hinges on targeted communication that builds buyer confidence through transparency and proven performance. Effective utilization of digital platforms—primarily company websites enriched with detailed case studies, equipment specifications, certification data, and client testimonials—allows for seamless dissemination of product value propositions.

Highlighting robust after-sales support, customizable solutions to suit varied production scales, and compliance with international standards reassures global procurement specialists about risk mitigation and investment returns.

Moreover, integrating advanced analytics on customer inquiry behavior and regional demand trends enables companies to tailor marketing campaigns that engage decision-makers precisely at critical buying stages.

For companies aiming to expand their footprint in international soybean oil markets, selecting the appropriate refining equipment requires a holistic evaluation of production goals, budget constraints, and regulatory landscapes.

Additionally, exporters should leverage digital marketing enriched with data-driven insights, articulate clear value propositions, and provide tailored after-sales services—including training and maintenance options—to heighten buyer confidence.

Explore our comprehensive range of high-performance refining equipment designed to meet diverse production scales and stringent international standards.

Request a Customized Quote & Consultation

Partner with us to unlock new export markets with equipment solutions tailored to your needs.