In the vast landscape of the global edible oil market, soybean oil stands out as a popular and versatile choice. Its production process, however, is a well - guarded secret that few are privy to. Today, we embark on a journey to uncover the intricate and fascinating production process behind soybean oil exports.

The journey of soybean oil begins with the arrival of soybeans at the production facility. These soybeans are sourced from reliable suppliers, with over 80% of them coming from regions known for high - quality soybean cultivation, such as the Midwest in the United States and parts of South America.

Once received, the soybeans go through a rigorous cleaning process. This step is crucial as it removes impurities like dirt, stones, and broken beans. Specialized cleaning equipment, such as vibrating screens and air separators, are used to ensure that only clean and intact soybeans proceed to the next stage. It's estimated that this cleaning process can remove up to 95% of the impurities.

After cleaning, the soybeans are broken into smaller pieces and dehulled. This process is carried out using crushers and dehullers. Breaking the soybeans increases the surface area, making it easier to extract the oil in the subsequent steps. The hulls, which account for about 8% of the soybean's weight, are removed. These hulls are not wasted; instead, they are often used as animal feed, demonstrating the company's commitment to resource utilization and environmental sustainability.

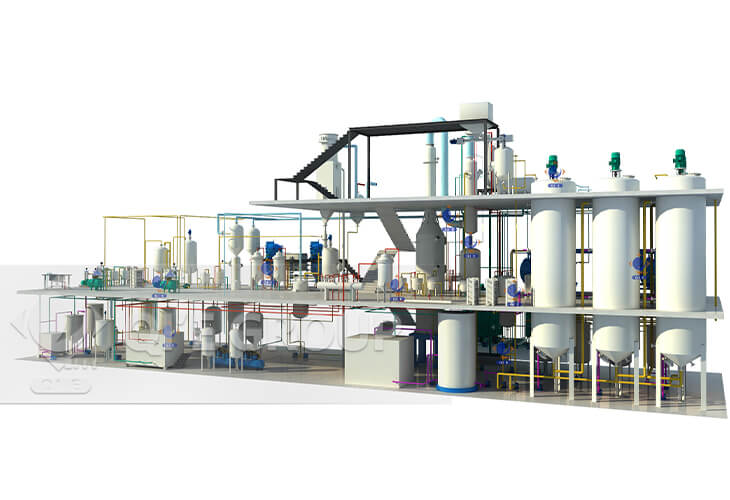

The extraction of soybean oil is a complex and highly technical process. There are two main methods: mechanical pressing and solvent extraction. In mechanical pressing, the crushed soybeans are pressed to squeeze out the oil. This method can extract about 70 - 80% of the oil. For a more efficient extraction, solvent extraction is often used in combination. A food - grade solvent, usually hexane, is used to dissolve the oil from the soybean flakes. After extraction, the solvent is removed through evaporation, leaving behind pure soybean oil. This combined method can achieve an extraction rate of up to 95%.

The extracted crude soybean oil is then refined to improve its quality, taste, and shelf - life. Refining involves several steps, including degumming, neutralization, bleaching, and deodorization. During these processes, impurities, free fatty acids, and odors are removed. The company adheres to strict quality control standards, ensuring that every batch of refined soybean oil meets international quality requirements.

Finally, the refined soybean oil is packaged into various containers, from small bottles for household use to large drums for industrial customers. The packaging is designed to protect the oil from light, air, and moisture, further extending its shelf - life.

In conclusion, the production of soybean oil is a highly professional and meticulous process. The company's strict quality control and the use of advanced technology ensure that every drop of soybean oil is of the highest quality. Moreover, the full utilization of resources reflects the company's commitment to environmental protection and sustainable development.

Contact us today to learn more about our soybean oil products and how we can meet your specific requirements. Our team of experts is standing by to assist you.