Soybean solvent extraction technology has emerged as the preferred method in the modern oil industry. Its core principle lies in using solvents, typically hexane, to extract oil from soybeans. This technique can achieve an oil recovery rate of over 98%, which is significantly higher than traditional mechanical pressing methods. In traditional pressing, the oil content remaining in the meal can be as high as 5 - 8%, while with solvent extraction, this residual oil content can be reduced to less than 1%.

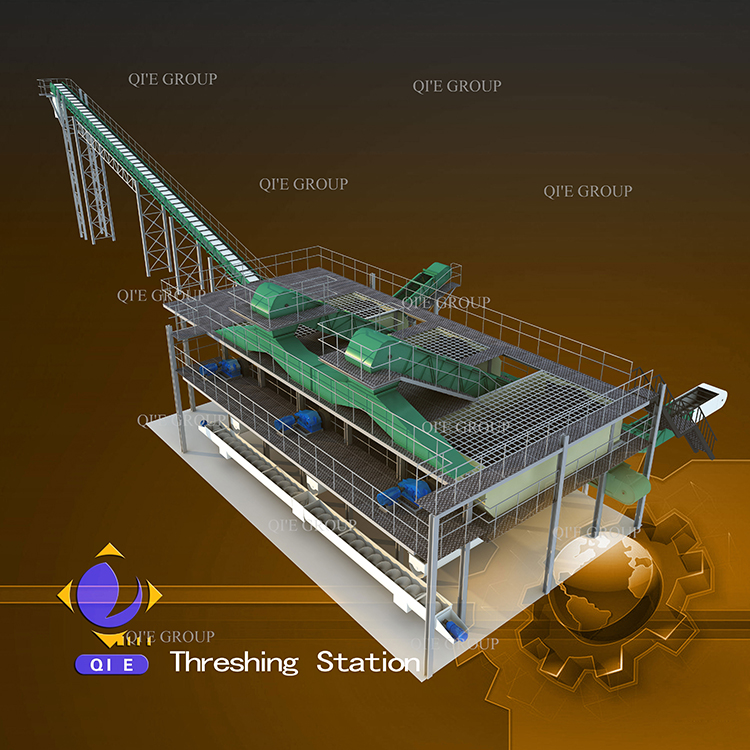

Before extraction, soybeans undergo a series of preparation steps, including cleaning, crushing, and cooking. Cleaning removes impurities, ensuring the quality of the final product. Crushing increases the surface area of soybeans, facilitating better contact with the solvent. Cooking can further denature the soybean cells, making the oil more accessible. These steps lay a solid foundation for subsequent extraction, and proper preparation can increase the extraction efficiency by about 10 - 15%.

In the extraction stage, hexane is used as a solvent to dissolve the oil in soybeans. The extraction equipment is designed to ensure maximum contact between the solvent and soybeans. Through counter - current extraction, the solvent can continuously extract oil from the soybeans, achieving a high - efficiency extraction process. This stage can significantly improve the oil recovery rate, and compared with simple immersion extraction, counter - current extraction can increase the oil recovery rate by 3 - 5 percentage points.

After extraction, the mixture of oil and solvent needs to be separated. Distillation is used to evaporate the solvent, leaving behind the pure oil. Advanced distillation equipment can ensure efficient separation while minimizing solvent loss. By optimizing the distillation process, the energy consumption can be reduced by more than 20% compared with traditional distillation methods.

Solvent recovery is an important part of the entire process. Recycling the solvent not only reduces costs but also has environmental benefits. Modern solvent recovery systems can achieve a solvent recovery rate of over 95%, which greatly reduces the cost of solvent consumption.

| Aspect | Mechanical Pressing | Solvent Extraction |

|---|---|---|

| Oil Recovery Rate | About 90 - 92% | Over 98% |

| Residual Oil in Meal | 5 - 8% | Less than 1% |

| Energy Consumption | Relatively high | Can be reduced by over 20% through optimization |

| Production Cost | Higher due to lower oil recovery | Lower with high - efficiency extraction and solvent recovery |

Soybean solvent extraction technology has a wide range of applications in various industries. In the feed industry, the high - quality soybean meal produced by this technology can provide rich protein sources for livestock and poultry. In the food industry, the extracted soybean oil is a common cooking oil. In the bio - diesel industry, soybean oil can be used as a raw material for bio - diesel production, contributing to sustainable energy development.

The future of soybean solvent extraction technology is moving towards green and sustainable development. On one hand, the use of green solvents to replace hexane is becoming a research hotspot. Green solvents are more environmentally friendly and can reduce potential environmental risks. On the other hand, the application of intelligent control systems in the extraction process can further improve production efficiency and product quality. For example, intelligent sensors can monitor the entire production process in real - time, adjusting parameters to achieve optimal production results.

If you are interested in learning more about how soybean solvent extraction technology can revolutionize your oil production process and bring significant economic benefits, click here to explore our advanced solutions.