In the global oilseed processing industry, understanding the distinct physical and chemical characteristics of various oilseeds is paramount to maximizing oil yield and product quality. Over nearly two decades operating in this sector, it has become evident that one-size-fits-all approaches fall short, often causing inefficiencies and increased operational costs. This article delves into the specific preprocessing and pressing requirements for key oilseed categories, such as soybeans, palm kernels, and flaxseeds, revealing how Penguin Group employs cutting-edge equipment and customized service models to empower processors worldwide.

Each oilseed type exhibits unique physical parameters—seed size, moisture level, hull thickness—and chemical attributes like oil content and fatty acid profile, which collectively dictate the preprocessing intensity and pressing parameters. For instance, soybeans generally have 18-20% oil content with moderate moisture (~13%), requiring gentle steam conditioning to preserve protein integrity. In contrast, palm kernels contain roughly 50% oil and dense shells that demand robust shelling and thermal treatment processes to free the kernel efficiently.

| Oilseed Type | Typical Oil Content (%) | Moisture Level (%) | Key Processing Consideration |

|---|---|---|---|

| Soybean | 18 - 20 | ~13 | Steam conditioning to optimize pressing & preserve protein |

| Palm Kernel | 45 - 50 | ~15 | Robust shelling & heat treatment for efficient kernel liberation |

| Flaxseed | 35 - 40 | ~8 - 10 | Careful breaking to avoid seed damage due to fragile hull |

The preprocessing stage is critical for removing impurities, optimizing particle size, and conditioning oilseeds to improve press performance and oil extraction. Key steps include:

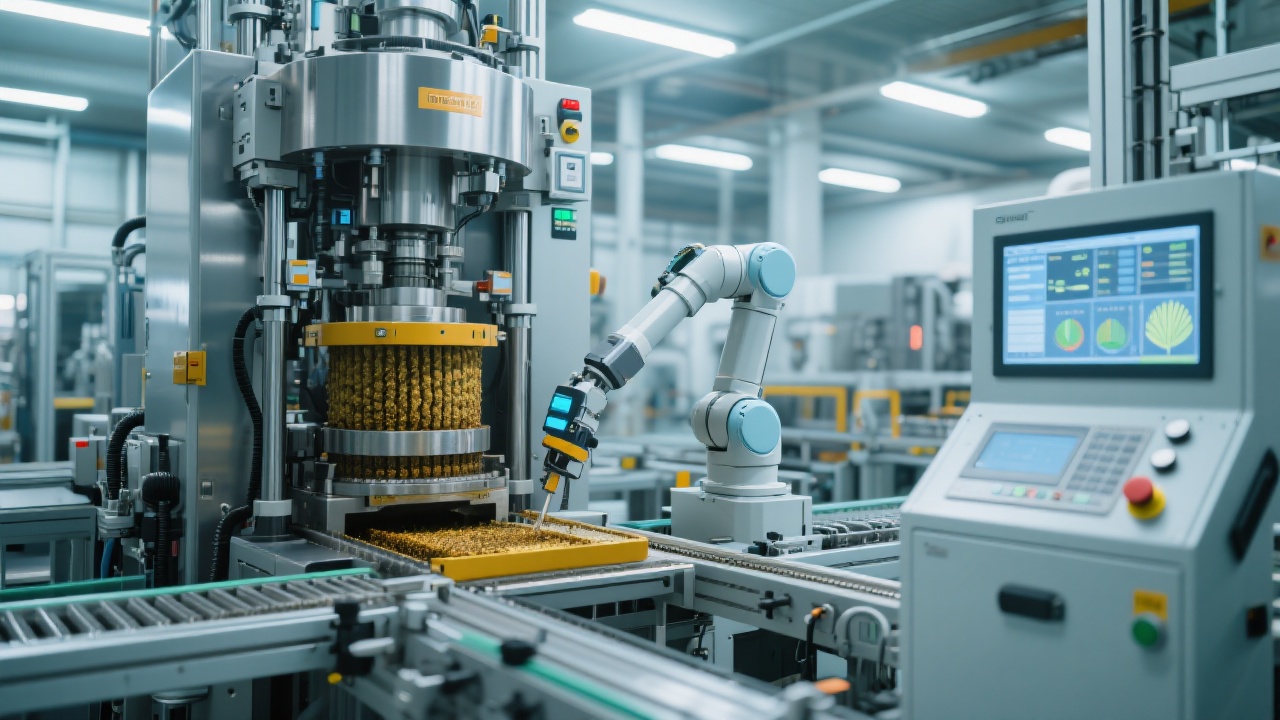

These preprocessing steps are device- and seed-specific. Penguin Group's line of equipment offers modular designs with adaptable configurations, enabling processors to seamlessly switch between oilseeds without downtime or costly retrofits.

The pressing stage demands precision engineering to balance throughput, oil quality, and residual oil content (cake). Key strategies include:

For example, a case with a Southeast Asian palm kernel processor working with Penguin’s advanced screw press saw an oil recovery increase of 12%, from 46% to 58%, over legacy equipment. Operational runtime improved with reduced maintenance intervals, thanks to precision components and automated lubrication systems.

Penguin Group’s philosophy centers around tailoring equipment to specific oilseed profiles and client production goals, incorporating:

A European client specializing in organic flaxseed oil cited a 30% reduction in downtime and a 15% improvement in oil purity after commissioning a fully customized preprocessing and pressing line by Penguin Group. The system’s temperature-sensitive conditioning protocol preserved omega-3 fatty acid integrity, a critical quality marker.

Leveraging proprietary R&D and field-tested designs, Penguin Group leads the industry in:

For instance, a South American soybean processor increased net profitability by 20% within a year by upgrading to Penguin’s integrated preprocessing and pressing solution, realizing softer meal texture thus enhancing downstream processing yields.

Ready to elevate your oilseed processing efficiency with tailored preprocessing and pressing solutions? Discover Customized Oilseed Processing Solutions Now