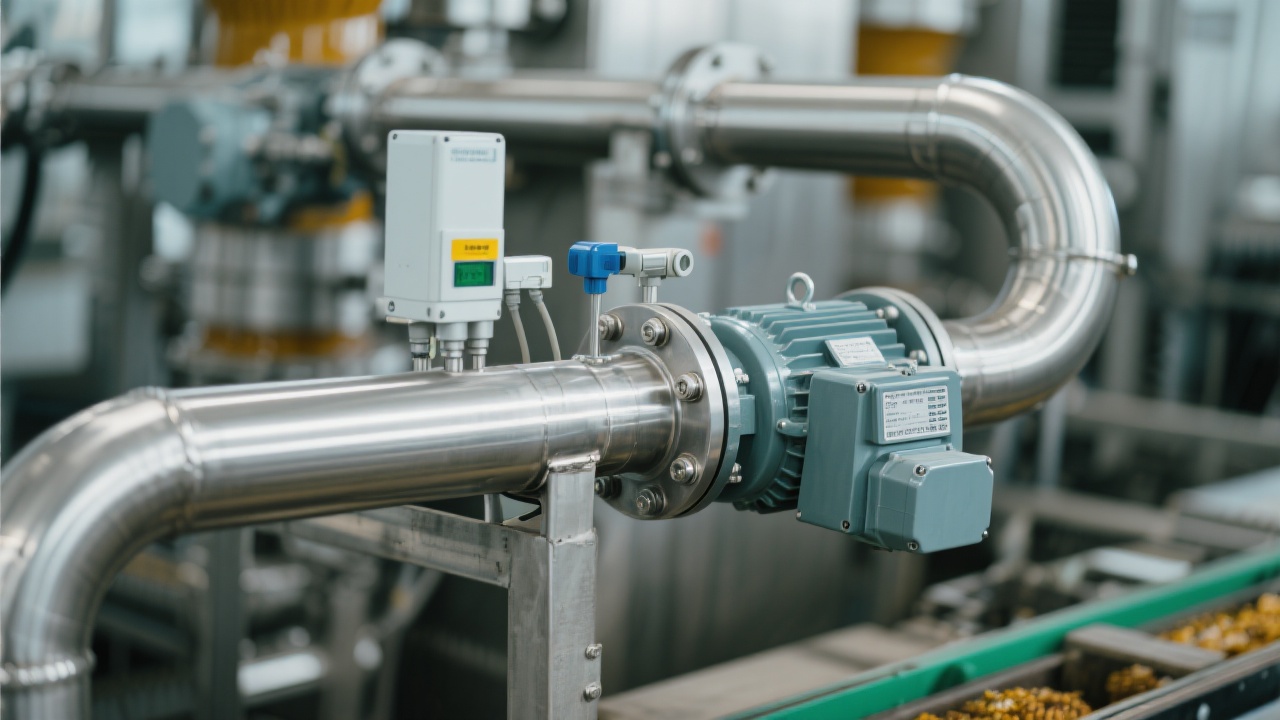

In the oil palm cultivation sector, enhancing processing efficiency while maintaining product quality remains a pivotal challenge. Over the past decade, advancements in palm kernel oil production line equipment have dramatically transformed the industry landscape. Leading manufacturers now emphasize customized, high-efficiency machinery designed to meet the unique demands of large- and small-scale plantations, optimizing extraction and refining processes.

Contemporary production lines integrate cutting-edge technology that substantially reduces downtime and maximizes yield. These systems are engineered with features such as:

A notable case from Southeast Asia demonstrates these systems can increase oil extraction efficiency by up to 18% compared to traditional equipment, resulting in notable raw material savings.

The integration of intelligent process controls and real-time monitoring systems distinguishes advanced palm kernel oil production lines. These allow operators to promptly adjust settings in response to fluctuating input quality or processing conditions, thereby maintaining optimal output.

A tailored approach is crucial. For example, medium-scale plantation clients in West Africa collaborated with equipment providers to develop bespoke machines adapted to local palm kernel varieties and environmental conditions. The resulting production lines showed a 20% reduction in energy consumption and cut maintenance intervals by nearly half.

Consider the example of a large Malaysian palm oil plantation facing bottlenecks in its extraction phase, resulting in elevated production costs and inconsistent oil quality. By implementing an advanced, fully automated palm kernel oil production line featuring enhanced screw press technology and integrated purification units, the company achieved:

| Performance Metric | Before Upgrade | After Upgrade |

|---|---|---|

| Oil Extraction Yield (%) | 42% | 50% |

| Energy Consumption (kWh/ton) | 450 | 360 |

| Maintenance Downtime (hours/month) | 18 | 8 |

| Product Quality Consistency (Grade A %) | 75% | 92% |

These improvements translated into significant annual operational savings and enabled the enterprise to secure new contracts due to higher product quality standards.

Investing in advanced palm kernel oil production equipment unlocks multifaceted value. Besides immediate productivity gains, companies report:

These aspects contribute directly to fortifying market competitiveness and brand reputation, essential in an industry increasingly governed by environmental standards and consumer demand for traceability.

Leading suppliers actively incorporate client feedback and regional processing requirements into production line customization. This co-development approach ensures equipment matches the evolving industry dynamics—from handling diverse palm kernel moisture contents to complying with local labor regulations.

Moreover, dedicated after-sales support and rapid parts replacement further bolster customer confidence, underlining the brand’s authority in the oil palm sector.

The deployment of technologically advanced, tailor-made palm kernel oil production lines delivers measurable enhancements in efficiency, quality, and cost-effectiveness. Beyond operational gains, such equipment supports sustainable development goals, enabling producers to thrive in a competitive global marketplace.

For industry stakeholders aiming to elevate their processing capabilities and profitability, investing in innovative equipment backed by proven case studies is indispensable.

Discover tailored solutions that align perfectly with your operational needs. Explore our custom palm kernel oil production equipment now and elevate your business performance.