In the soybean oil processing industry, traditional methods have long been plagued by several limitations. Manual operations are not only labor - intensive but also prone to human errors, which can lead to inconsistent product quality. For example, in a traditional soybean oil processing plant, the average production capacity might be around 50 - 80 tons per day, and the energy consumption could be as high as 150 - 200 kWh per ton of processed soybeans. Additionally, the lack of precise control in traditional processes often results in lower oil extraction rates, typically around 16% - 18%.

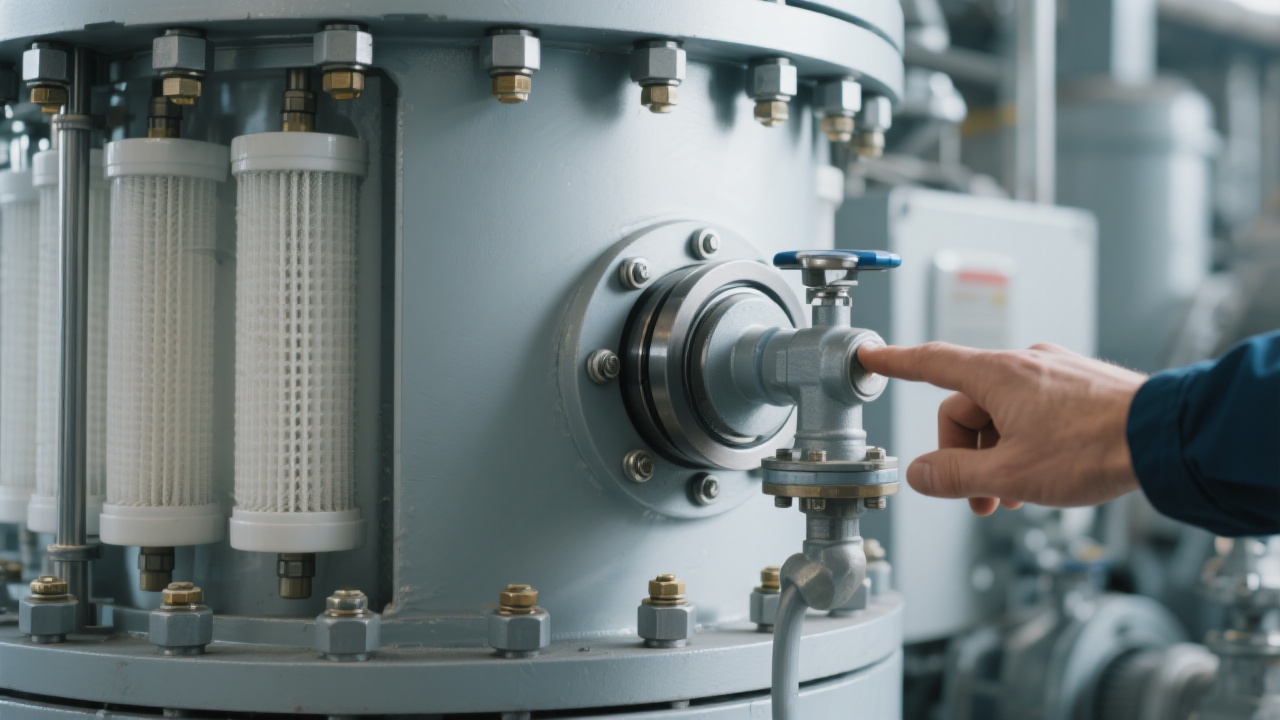

The screw press is a key piece of equipment in soybean oil processing. By applying automation technology, it can achieve continuous and precise operation. The automation system can adjust the pressing speed and pressure according to the moisture content and quality of soybeans. For instance, in a plant using our automated screw press, the oil extraction rate increased from 18% to 20%, and the energy consumption decreased by 15%. The automated screw press can also self - diagnose faults, reducing maintenance time and costs.

In the case of hydraulic presses, automation allows for accurate control of the pressing force and time. Traditional hydraulic presses rely on manual adjustment, which is time - consuming and inaccurate. Our automated hydraulic press can complete a pressing cycle in 20% less time, increasing the daily production capacity by 10% - 15%. Moreover, the consistency of the oil quality is significantly improved, with the acid value and peroxide value within a more stable range.

Solvent extraction is a crucial step in obtaining high - quality soybean oil. Automated solvent extraction equipment can precisely control the temperature, solvent flow rate, and extraction time. In a real - world case, a plant using our automated solvent extraction equipment reduced the solvent consumption by 25% while increasing the oil yield by 3%. The automation system can also monitor the solvent concentration in the exhaust gas, ensuring environmental compliance.

Refining is the final stage to improve the quality of soybean oil. Our automated refining equipment can adjust the dosage of refining agents in real - time according to the quality of the crude oil. This results in a more efficient refining process, reducing the refining loss by 8% - 10%. The color, odor, and other quality indicators of the refined oil are more stable and meet higher standards.

Automation brings multiple benefits to soybean oil processing. Firstly, the production capacity is significantly increased. A plant with our automated equipment can achieve a daily production of 100 - 120 tons, a 30% - 50% increase compared to traditional methods. Secondly, the product quality is more stable, which is crucial for market competitiveness. Thirdly, the operation safety is enhanced as the automated system can prevent over - pressure, over - temperature, and other dangerous situations.

A medium - sized soybean oil processing plant in South America replaced its traditional equipment with our automated solutions. After three months of operation, the production capacity increased from 60 tons per day to 90 tons per day. The energy consumption per ton of processed soybeans decreased from 180 kWh to 150 kWh, and the labor cost was reduced by 30% as fewer workers were needed for operation and monitoring.

Our soybean oil processing equipment is designed with high scalability. Whether you are a small - scale factory with a daily production of 20 - 30 tons or a large - scale enterprise aiming for 200 - 300 tons per day, our equipment can be customized and expanded. In addition, we provide a clear path for future upgrades. As new technologies emerge, our customers can easily upgrade their existing equipment to keep up with the industry trends.

Our company's soybean oil processing equipment stands out in the market due to its high - efficiency automation technology. We are at the forefront of the industry in terms of energy - saving, high - yield, and stable quality. By choosing our equipment, customers can not only reduce production costs but also improve their market competitiveness. Our technical support team provides 24/7 service to ensure the smooth operation of the equipment.

If you are looking for reliable and efficient soybean oil processing equipment, don't hesitate to contact us. We are committed to providing you with the best solutions tailored to your needs. Do you have similar challenges in your soybean oil processing business? Share your specific situation with us, and we'll send you 3 case studies of successful solutions from the same industry.