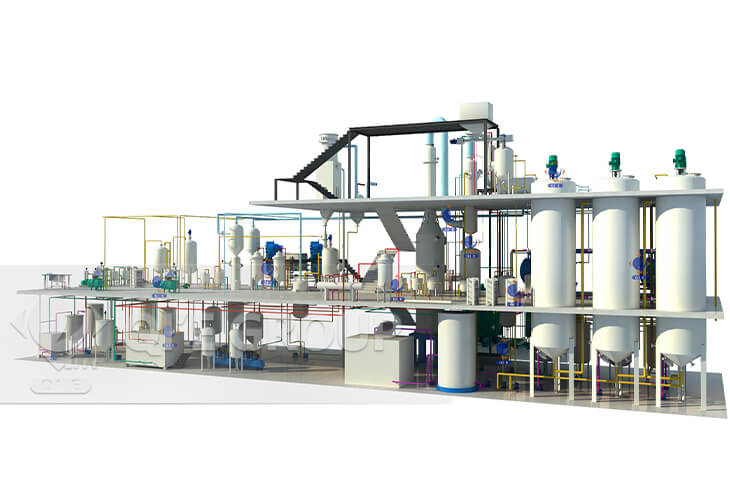

In the competitive global B2B marketplace, plant oil producers face growing demands for high efficiency, environmental compliance, and scalable solutions. Leveraging intelligent manufacturing technologies is no longer optional but essential to achieve sustainable growth and operational excellence. A key breakthrough in this landscape is the application of large-scale hydraulic and pre-press machines engineered specifically for plant oil processing.

\n\n \n\n

\n\n

These large hydraulic/pre-press machines integrate cutting-edge intelligent manufacturing technologies—such as automated pressure control, real-time monitoring sensors, and remote diagnostics—to enable smarter, safer, and more energy-efficient plant oil extraction. Driven by robust solid-state designs and durable components, the equipment ensures consistent output quality and enhanced operational uptime. Ease of operation paired with proactive maintenance alerts drastically reduces downtime and simplifies workforce training requirements, optimizing overall productivity.

\n\n| Feature | \nBenefit | \n

|---|---|

| Automated Pressure Regulation | \nMaintains optimal pressing conditions for maximum oil yield | \n

| Durable Engineering | \nEnsures stable long-term operation under heavy industrial load | \n

| Energy-Efficient Components | \nDecreases power consumption by up to 20%, lowering operational costs | \n

| User-Friendly Interface | \nFacilitates quick staff onboarding and reduces human error | \n

The large hydraulic/pre-press machines demonstrate remarkable adaptability, processing a wide range of plant oils including soybean, sunflower, palm, rapeseed, and coconut oils. Their adjustable pressure settings and modular design allow fine-tuning according to seed or kernel characteristics, optimizing extraction rates without compromising oil quality. This flexibility enables manufacturers to diversify product lines or switch raw materials efficiently, enhancing responsiveness to market fluctuations.

\n\n \n\n

\n\n

Implementation of these machines facilitates a transformative shift towards intelligent, eco-friendly production processes. Embedded sensors and IoT connectivity provide plant managers with actionable data on machine health, pressure consistency, and energy consumption, fostering informed decision-making and predictive maintenance. Industry benchmarks show that plants incorporating intelligent hydraulic pressing technologies achieve up to 15% higher throughput while reducing waste and power use, aligning with global sustainability initiatives.

\n\nMoreover, the use of hydraulic pre-pressing reduces reliance on high-temperature roasting, minimizing energy-intensive practices and preserving bioactive compounds in oils. Environmental impact assessments cite up to a 25% decrease in carbon emissions compared to traditional mechanical pressing methods.

\n\n \n\n

\n\n

Numerous multinational plant oil producers report tangible benefits after integrating large hydraulic/pre-press machines within their production lines. Key advantages include:

\n\nWith these measurable impacts, plant oil manufacturers are better positioned to capture emerging market opportunities, meet stringent regulatory requirements, and satisfy consumer demand for sustainably produced oils.

\n\nUnlock the full potential of your plant oil processing with our advanced large hydraulic/pre-press machines. Experience efficient, green, and intelligent manufacturing that propels your business forward in the global marketplace.

\n \n