In the ever-evolving sesame oil industry, operational efficiency and product quality have become pivotal for businesses seeking sustainable growth. A recent case of a food processing company adopting our state-of-the-art sesame oil production line affirms this paradigm shift. By leveraging our high-efficiency, energy-saving equipment, the company realized a 35% increase in output capacity and a 25% reduction in operational costs within six months—demonstrating how modern production technologies can decisively impact the bottom line.

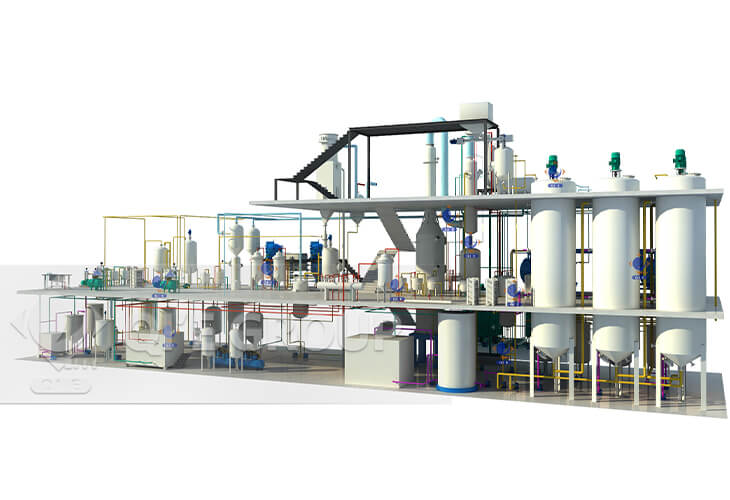

The key to this transformation lies in the advanced design of the entire production line, which incorporates automated processes from sesame cleaning to final bottling. Our integrated system includes:

Quality assurance permeates every step of the production process. Real-time monitoring systems track temperature, pressure, and humidity to ensure optimal extraction and storage conditions. Rigorous sampling and laboratory analysis verify the oil’s purity, moisture content, and fatty acid profile.

| Quality Parameter | Industry Standard | Our Production Line Result |

|---|---|---|

| Oil Purity (%) | ≥ 99.5 | 99.8 |

| Moisture Content (%) | ≤ 0.2 | 0.15 |

| Oxidative Stability (hours) | ≥ 40 | 45 |

Market research highlights that global demand for premium sesame oil is projected to grow at a compound annual growth rate (CAGR) of 7.4% through 2028, driven by rising consumer awareness of the oil’s health benefits and flavor profile. Meanwhile, sustainability pressures push enterprises toward low-energy, low-waste manufacturing models.

Investing in energy-saving, automated production lines not only aligns with these market imperatives but also enhances operational resilience. Companies report average payback periods of under three years owing to reduced labor costs, minimized downtime, and optimized raw material utilization.

Adopting a cutting-edge sesame oil production line is more than just an equipment upgrade—it’s a strategic move unlocking enhanced capacity, cost efficiency, and consistent product excellence. Our expert team is ready to provide personalized consultation to help you evaluate potential ROI and design a tailor-made solution to fit your operational goals.

Have questions about upgrading your production line? Leave a comment below or reach out directly—our team is here to support your journey toward industry leadership.